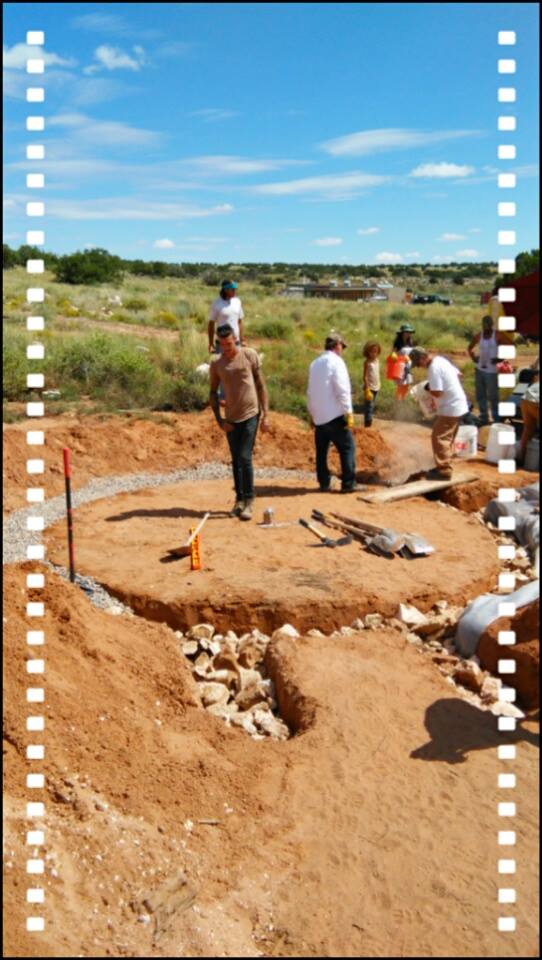

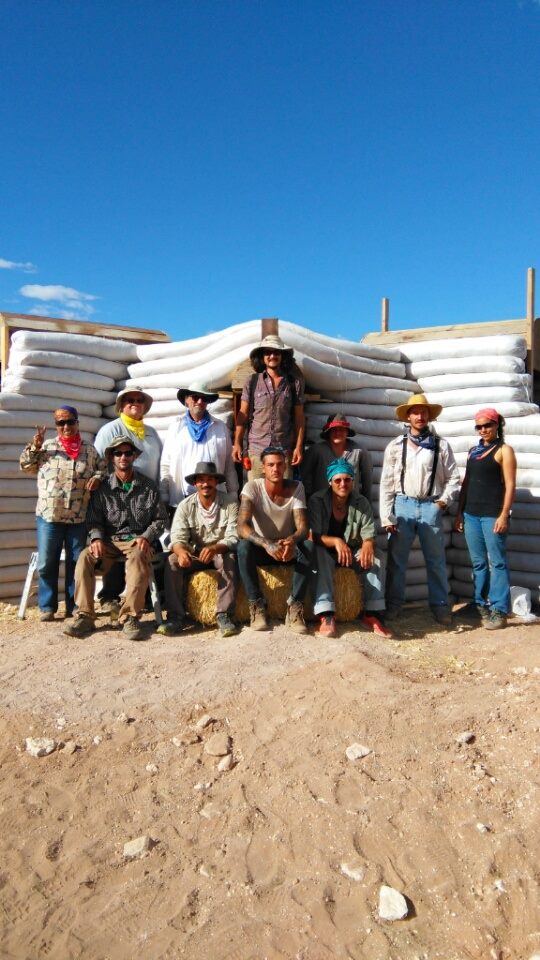

Arizona Earthbag building workshop

This workshop was held in northern Arizona. Students came from around the world and all walks of life to learn the process of building an earthbag dome home. This is the strongest and most affordable way to build a home. Total materials cost for this build was around $1,000

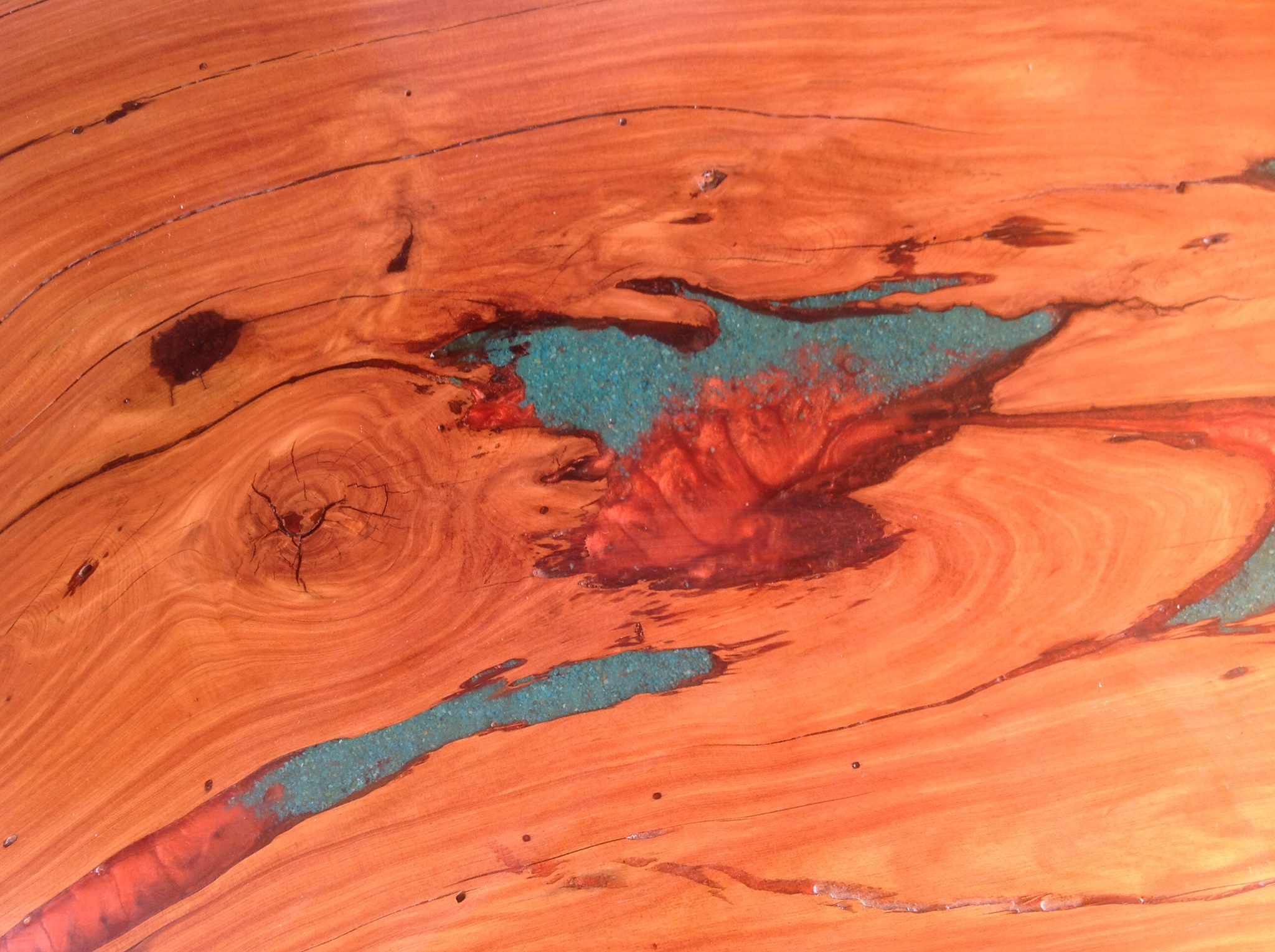

Arizona Earthship build

The Arizona build was a modified packaged Earthship design. With an amazing crew led by Justin Dudley, this beautiful 1200sqft off-grid home was built over one summer. This home features passive solar heating, cooling tubes, grey and black water treatment, pallet and dab interior walls, a recycled pallet wood kitchen with custom cabinets and juniper slab counter tops, as well as locally harvested flagstone floors.

Detroit Build

The Earthship Detroit build was the brain child of master builder Justin Dudley. This miniature Earthship was built right in front of Priest elementary school in southwest Detroit, Michigan. The purpose of the structure was to open the minds of the children and community to the world of sustainable design and the concept of using recycled building materials. The building is currently being used as an outdoor classroom and is supplying plant starts for the school gardens. Project materials were largely recycled and the children of the school helped with every step from beginning to end. Team consensuses rates this our most satisfying build to date.

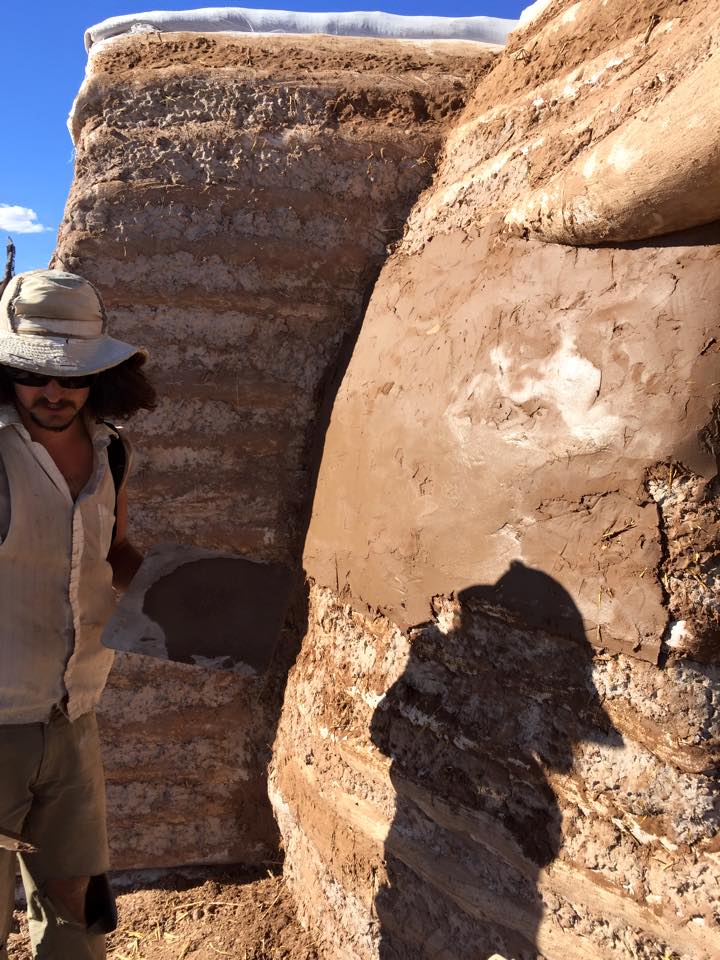

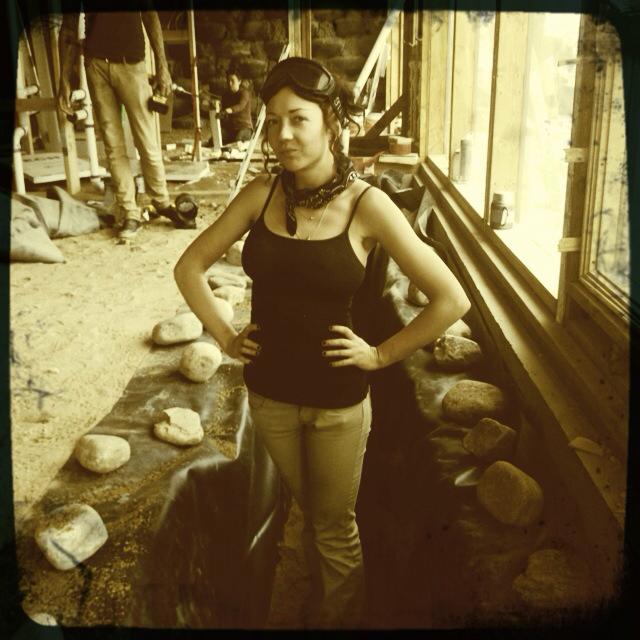

Colorado Passive solar rammed earth build

The Squibb home build was the concept of owner builder Mark Squibb. After Mark's home was burned in a forest fire, Robert Parson led the task of helping Mark turn his big dreams into a reality. This home is extreme in every sense of the word. It featured over 4,000sqft of living space, 2 story layout, 30’ tall greenhouse with grey water treatment, cooling tubes and Earthship/ timber-framing hybrid design. We harvested all the lumber to build this home from dead standing trees from the fire, Then processed that wood on a portable sawmill mark purchased. The mill was an invaluable tool though out the build process and was eventually sold saving the project over 70k in lumber costs.